Contact Us Today

For your CNC Turning and Milling Services!

Contact Us

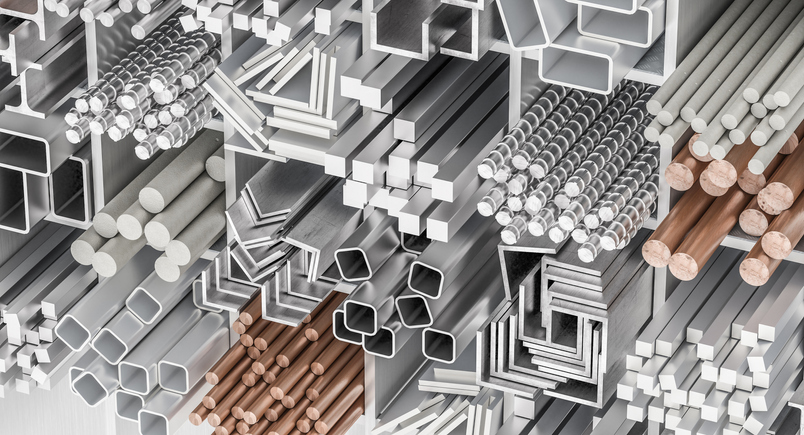

Expert machinists have the capabilities and skills to transform your chosen CNC materials into a machined part precisely machined to meet your unique requirements. CNC machining is swift and accurate, and its versatility allows you to specialize your design and materials to best suit your needs. From metal to plastic composites, there’s a wide array of CNC machining materials to choose from in order to produce strong, durable parts ready to serve your project’s needs.

As you consider which materials might be best suited for your needs, there’s a range of questions you can ask to determine which material matches your requirements. What environment must your part perform in? Do you need your machined part to be conductive, or have a specific color or detail level? These questions will help you determine which CNC machining materials you should consider.

Below, we’ve broken down the key advantages of common CNC materials, the differences between them, and what questions to consider when deciding which to use. Read on to learn how to choose the right CNC machining materials for your project to ensure your final product is polished and prepared for your intended use.

Metal is the most commonly used material in CNC milling and turning due to its rigidity and strength. The level of detail and demand CNC machining allows is supported by metal’s unique qualities and strength. Popular metal choices for CNC machining materials include aluminum, steel, brass, copper, and titanium.

Plastic is a rigid, easy-to-machine material that can produce quality parts and prototypes. Some common plastics used in CNC machining include PEEK, acrylic, and nylon.

To ensure your chosen material will be suitable for your unique applications, consider the following questions.

As you evaluate your options, consider talking to an engineering expert to help you find your best choice.

We’re Here to Help: Learn more about how Aztalan can help you choose the best materials for your CNC needs.

With more than 50 years of experience delivering high-quality CNC parts and prototypes to businesses in need across the U.S., Aztalan has the skills, equipment, and dedication to push your project forward. We employ expert engineers who use advanced automation and innovative technology to boost the accuracy of your product while keeping it within tight timelines and your budget. As an ISO-9001 and ISO-13458-certified company, we prioritize quality in everything we do and maintain strict quality standards to ensure your final product is precisely made and ready for market.

Aztalan passionately serves clients with efficient, accurate engineering every time, and we offer comprehensive services to completely meet your needs. Whether you require CNC milling, turning, swiss-turning, assembly, ultrasonic cleaning, or more, we combine our skills with our commitment to service and holistically meet your needs.

Our expert engineers are here to help you choose the best CNC machining materials for your next project. Contact our team today to get started.